Progressive Die

Below is an example of the upper shoe on one of our progressive dies. It is composed of 13 different stations. They include pierces, forms, idles, and a cut-off. To the left you will see the actual strip and finished product for this die.

Secondary Die

The Wire Shop can produce dies to perform many different secondary operations. Below-left is an example of a die made to produce slots in an extruded plastic part from one of our current customers. In this particular case, our customer supplies us with cut-to-length blanks. We then designed a die to pierce the slots required in the finished part.

Compound

The Wire Shop has a wide variety of experience with compound dies. Unlike a progressive die, a compound die allows you to get your completed blank in one station. This allows you to get a smaller die that saves you from needing extra operations for piercing and the like.

Flying cut-off

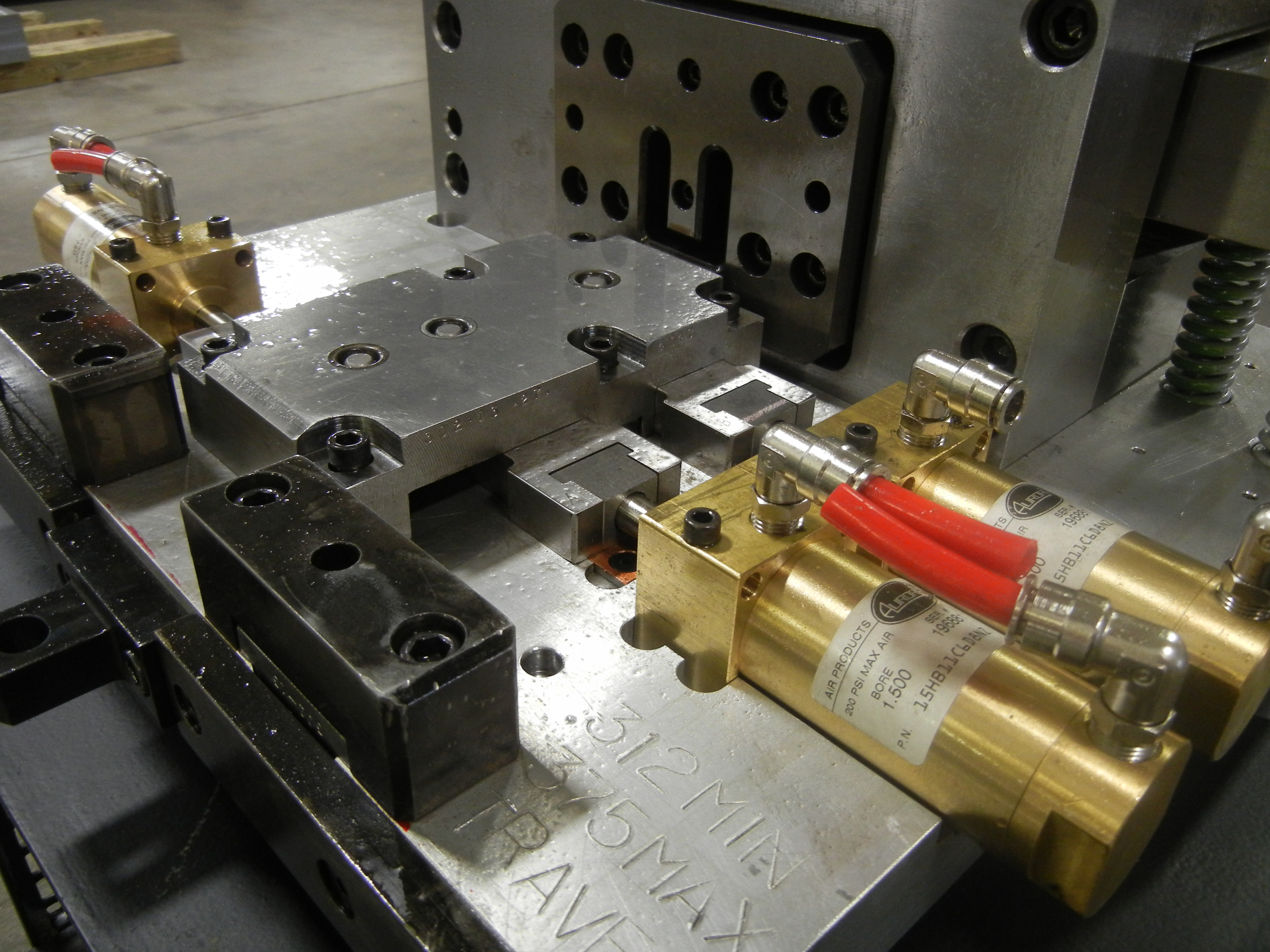

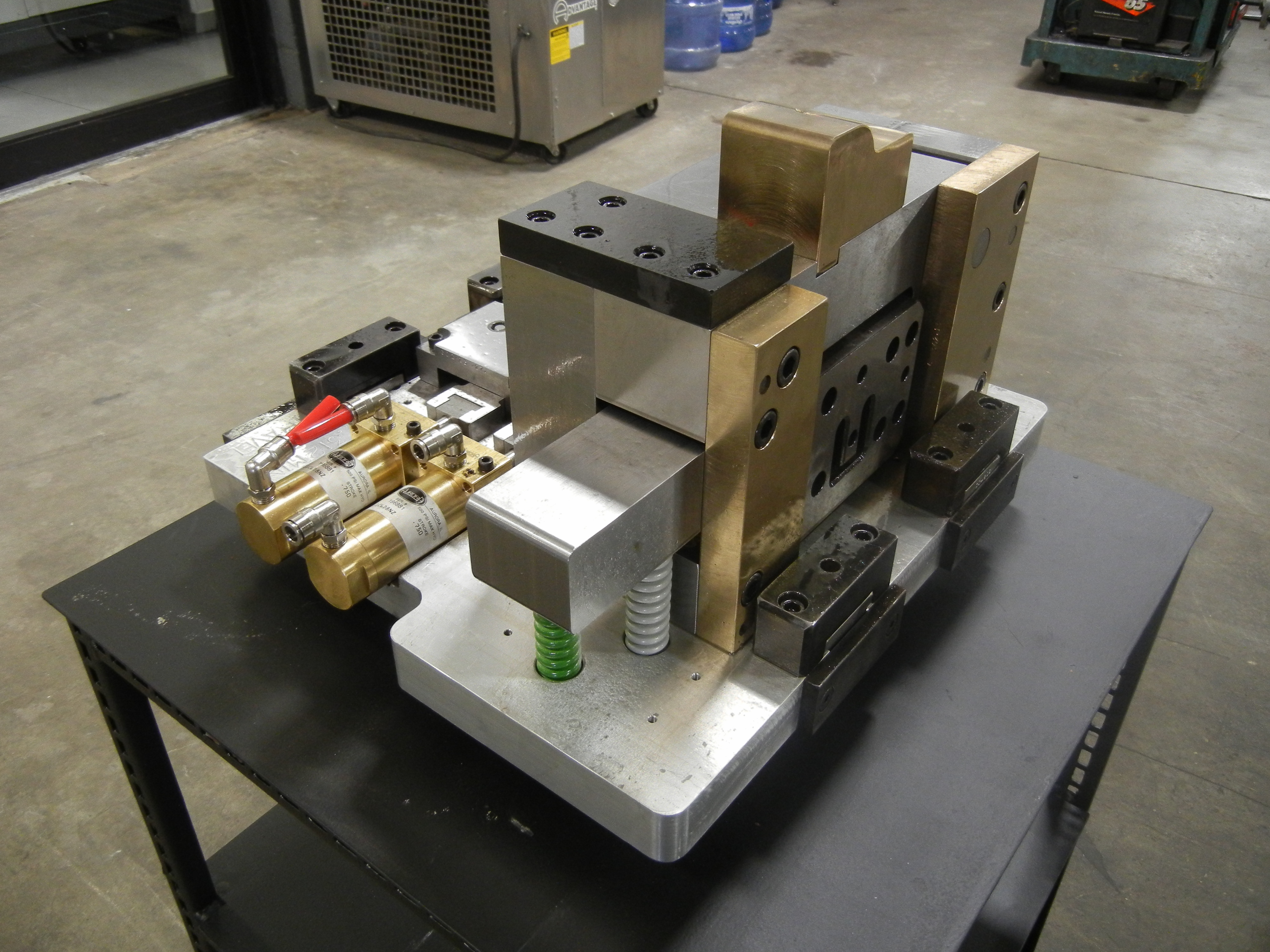

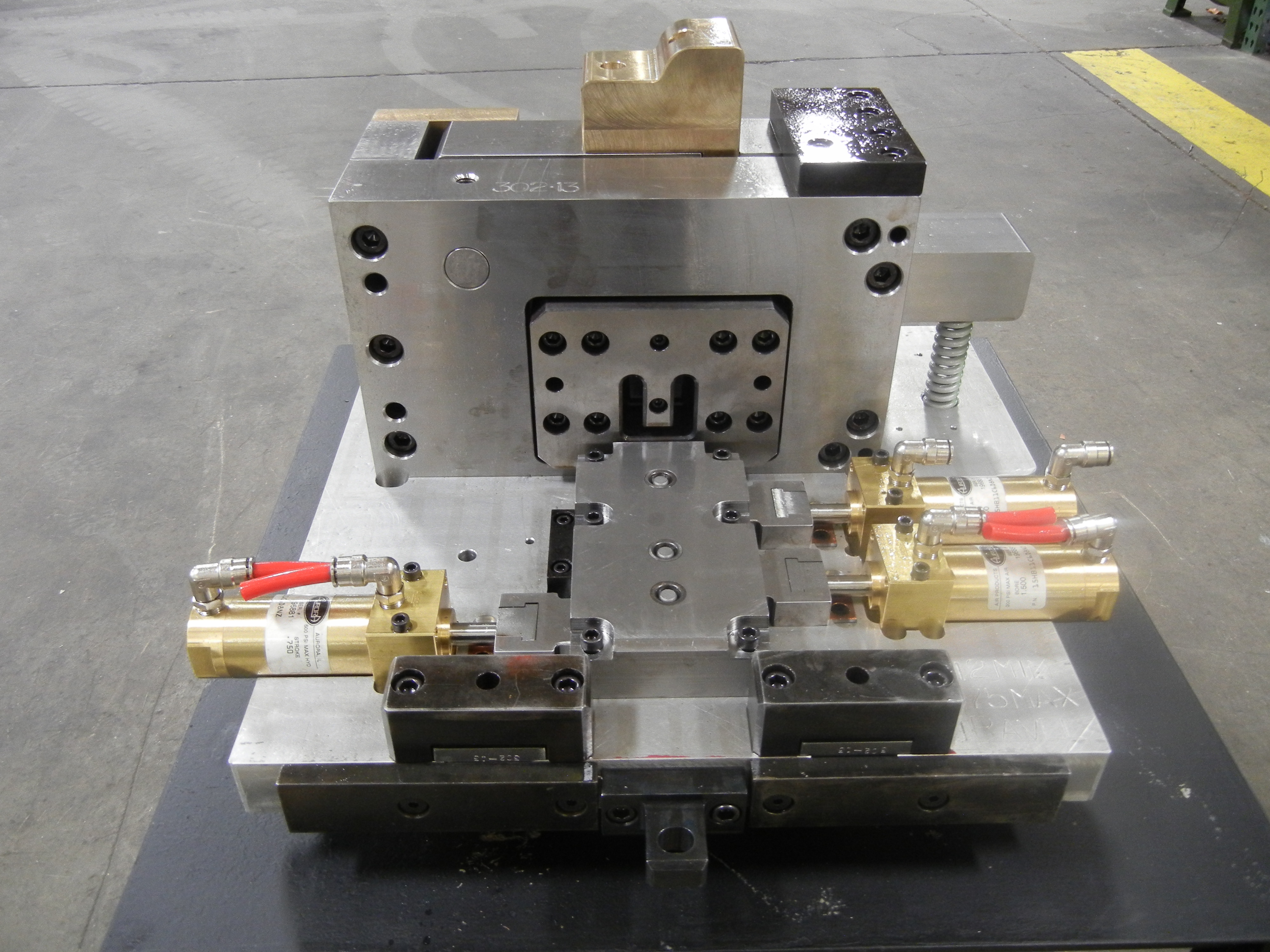

The Wire Shop has extensive experience in cut-off dies for the roll forming industry. Our sister company, Formasters Corporation, offers a full range of roll formed and stamped products. We produce cut-off dies that are used in the roll forming process. Below, you will find an example of one of the dies we built.

The flying cut-off die is mounted into an air press, which we also manufacture. As the material exits the roll former, it is sent into the cut off die. The die is electronically set to cut off to the length, that you pre-set, for your product.

Pre-notch

The Wire Shop will also build pre-notch dies to meet your specific needs. We design our pre-notch dies to go along with your roll-forming applications. By using gags in the tooling, we are able to allow you to make many different parts out of the same pre-notch die.

Draw

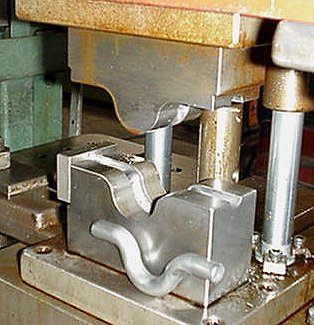

The example below shows a stretch web isolating the part form the strip. The cup is formed and held in the strip and then pushed out. For more information please email The Wire Shop.

Form Dies

The Wire Shop has extensive experience in the design and manufacturing of a variety of form dies for use in both punch and brake presses.

Below you can see a few examples of our single hit formed parts.